FAA Lights for Wind Turbines: Illuminating the Path to Safer Renewable Energy

As wind energy expands across the U.S., the Federal Aviation Administration (FAA) mandates specific lighting requirements to ensure wind turbines do not pose hazards to low-flying aircraft. FAA lights for wind turbines serve as critical visual markers, reducing collision risks while supporting clean energy growth. This article explores the regulatory framework, technological advancements, and best practices for implementing compliant FAA lights for wind turbines.

Why Wind Turbines Require FAA Lighting

1. Height and Obstruction Risks

Most modern wind turbines exceed 200 feet (61 meters), requiring lighting per FAA Advisory Circular AC 70/7460-1L.

Unmarked turbines create navigation hazards for helicopters, crop dusters, and small aircraft.

2. Compliance with Aviation Safety Regulations

The FAA categorizes wind farms as "obstructions to air navigation."

Proper lighting ensures compliance with 14 CFR Part 77 and prevents legal liabilities.

3. Day and Night Visibility

FAA lights for wind turbines must be visible in all conditions:

Daytime: High-intensity white strobes

Nighttime: Medium-intensity red lights

Types of FAA-Approved Lighting Systems

1. Medium-Intensity Red Lights (L-864)

Used for turbines under 500 feet (152 meters).

| faa lights for wind turbines |

Steady-burning or flashing red lights for nighttime visibility.

2. High-Intensity White Strobe Lights (L-856)

Required for turbines taller than 500 feet (152 meters).

Bright white flashes visible up to 5-10 nautical miles.

3. Dual Lighting Systems

Some locations require both red and white lights for optimal visibility.

Automatically adjusts based on ambient light conditions.

FAA Lighting Regulations for Wind Farms

1. Lighting Configuration

Top-mounted lights on each turbine.

| faa lights for wind turbine |

Mid-level lighting for very tall turbines.

Perimeter lighting for large wind farms.

2. Flash Rate and Synchronization

20-60 flashes per minute (FAA standard).

Synchronized flashing across all turbines to avoid pilot confusion.

3. Light Shielding and Mitigation

Downward shielding to reduce ground-level light pollution.

Automatic dimming in low-visibility conditions.

Technological Advancements in FAA-Compliant Lighting

1. LED Lighting Solutions

50% energy savings compared to traditional xenon strobes.

Longer lifespan (10+ years) with minimal maintenance.

2. Radar-Activated Lighting (RAL)

Lights activate only when aircraft are detected, reducing community light pollution.

Approved under FAA’s "Mitigation Beyond Standards" program.

3. Remote Monitoring & Smart Controls

IoT-enabled diagnostics for real-time fault detection.

Automated brightness adjustment based on weather conditions.

Challenges and Solutions

1. Community Light Pollution Concerns

Solution: Shielded fixtures and radar-activated systems.

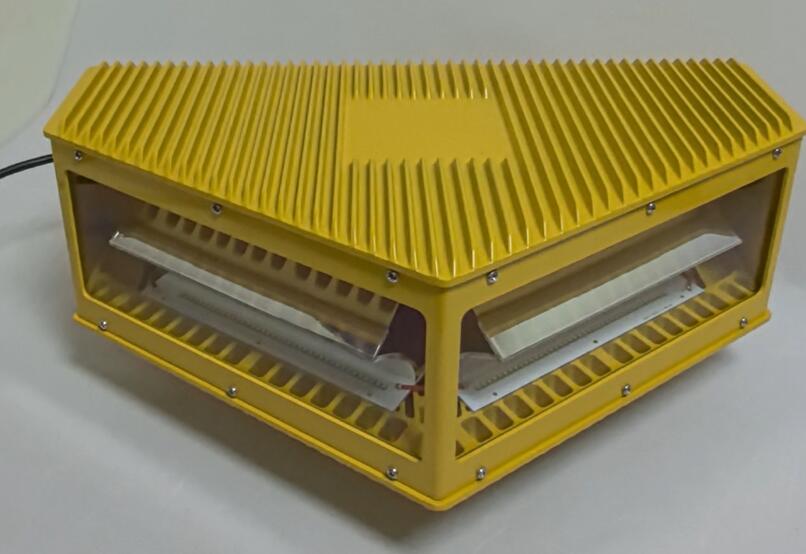

2. Harsh Environmental Conditions

Solution: Corrosion-resistant, weatherproof housings.

3. Maintenance Accessibility

Solution: Durable LED systems with remote monitoring.

Future Trends in FAA Wind Turbine Lighting

1. AI-Powered Adaptive Lighting

Machine learning adjusts flash patterns based on air traffic density.

2. Drone Detection Integration

ADS-B transponders to alert drones of turbine locations.

3. Solar-Powered FAA Lighting

Off-grid solutions for remote wind farms.

FAA lights for wind turbines are essential for balancing renewable energy expansion with aviation safety. As wind farms grow taller and more numerous, compliance with FAA lighting standards ensures safer skies while minimizing community impact. With advancements in LED technology, radar activation, and smart monitoring, the future of FAA lights for wind turbines promises greater efficiency and reduced environmental footprint.

By adhering to FAA regulations and adopting innovative lighting solutions, the wind energy industry can continue to thrive without compromising aviation safety.